Services

Portable Appliance Testing (PAT)

This ensures that all your electrical equipment is safe to use. The Electricity at Work Regulations 1989 makes it your responsibility to make sure all of your

electrical equipment is safe and compliant. If not, you could be putting yourself, your employees,

your office and ultimately your business at risk.

Our team of professional, experienced PAT testers carries out this service to many industries,

ensuring your business whether large or small remains compliant and safe.

TM44 Air Conditioning Inspection Reports

| Why TM44 Air Conditioning Inspections are required |

All air conditioning systems in buildings with an effective rated output of more than

12kw must be regularly inspected by an energy assessor. The inspections must be no more than five years apart or you may be fined. Having an air conditioning system audited by our accredited Energy Assessors are designed to improve efficiency, reduce energy consumption, operating costs and the carbon emissions of the system.

| What we can do for you |

Perhaps your business could benefit from identifying what AC systems are costing you the most, or which existing systems are the most inefficient? – Intelligent Carbon Solutions are not simply about compliance; we can highlight improvements to the operation of the existing systems, or look at opportunities to replace older, less energy efficient or over-sized systems with new more energy efficient options!

Your energy audit will include:

– A thorough visual assessment of your air conditioning system

– An examination of your ventilation equipment and controls

– Asset List (optional)

| Your Ace-Wizard Report |

– We give you a comprehensive energy report using Ace-Wizard

– The production of a compliance report and certificate of inspection

The detailed report tells you; the current efficiency of your equipment, suggestions for improving the efficiency of your equipment, estimated annual cost projections and potential savings, overall condition of your AC equipment, any issues and suggested actions and how to reduce your air conditioning use.

We are proud approved users of the Ace-Wizard inspection system for the production of air conditioning TM44 reports. Ace-Wizard is a now used on over 30% of all TM44 air conditioning inspections in the UK.

| Benefits |

– These comprehensive reports can show you/or your clients a projection of operating costs and energy usage for each AC system | Chiller | AHU within a given building.

– Our dedicated assessor will utilise his/her findings from their thorough site inspection to show projections of any potential energy and cost savings – (through implementing their recommendations). So in turn help your business reduce the impact of your AC system on your energy bills!

LPT

Maintenence

For a lightning protection system to function as designed in the event of a lightning strike, it is essential that the lightning conductor system is maintained and kept in good order.

Please call Stellar Compliance for maintenance, repairs or full upgrades to BS EN 62305.

Test & Inspection

Section 5 of the Electricity at Work Act 1989 states; “that all lightning protection systems are maintained and tested at regular intervals, preferably not exceeding 12 months”

It is important that all lightning protection systems should be tested by a specialist at least every 12 months but we always recommend testing is carried out every 11 months. This gradually builds up a full picture of the earthing system and allows for any seasonal variations.

Existing BS 6651 can still be tested and certified to this standard. Post 2008 systems are tested and certified to BS EN 62305. ESE systems are tested and certified to NFC-17-102. An engineer’s inspection report will accompany the system certificate with details of any repairs/recommendations required. All Lightning Protection Testing service inspections are carried out by a fully qualified lightning conductor engineers. All test instruments are calibrated and certified to ensure accurate results.

EML

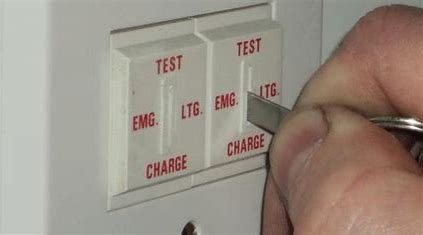

Is emergency light testing a legal requirement?

UK fire regulations stipulate that your emergency lights should be turned on and off monthly to test them and have a full service once a year. The latest British Standard recommends that you have a 3-hour emergency lighting test once a year, during which your main light circuit should be switched off and your emergency lights left on for a 3 hour period to find out of any batteries need replacing.

Stellar Compliance maintain these essential emergencies lighting systems, ensuring compliance with BS 5266, BS EN 50172 and The Health and Safety (Safety Signs and Signals) Regulations 1996.

BS5266 requires an up-to-date logbook to be kept that details the type of Emergency lighting installed along with all events and checks to be logged. Stellar Compliance will supply a comprehensive asset register that fully details the type of emergency lighting system installed, location of each fitting and whether the fittings pass or fail the illumination or duration tests.

All further inspections should then be recorded within the logbook.

Maintenance, Servicing & Repair

Once the initial inspection is completed, we will provide a full written report on the condition of the system and if any defects or non-conformances were recorded along with a detailed cost summary to rectify the faults for your consideration.

TML

Thermographic surveys detect abnormally high temperatures and are a non-disruptive way of inspecting installations, so your business operation isn’t affected.

What are the reasons for high temperatures?

- A fault with the equipment

- Overloading sockets in your workplace

- Loose connections

- The age of the equipment – gradual wear and tear

Why should you undertake a thermographic survey?

These surveys help you identify hot spots in electrical systems that you might not be able to see and makes sure that they are running safely. With a thermographic survey, you can rest assured that any faults are dealt with and, as it is non-disruptive in nature, there is no down time for you to be affected by.

EICR

Purpose of EICR

The main purpose of this report is to investigate and show, so far as is reasonably practicable, any factors that could impair the safety of the installation.- Safety against the effects of electric shock and burns

- Protection of property and against fire and heat damage caused by defects

- Confirmation that the electrical installation is not damaged or deteriorated

- Identification of non-compliance with BS7671 Wiring Regulations

Upon completion of inspection a report will be raised and sent along with any remedial recommendations that have been identified.

Remedial and Installation

Whether you require remedial works carried out following an EICR inspection or require installation works carried out Stellar Compliance will be a happy to attend site and survey works however big or small the job may be.

Upon completion of works either a minor works certificate or installation certificate will be raised and sent to you to ensure that your system meets BS7671 standards.

We'll Contact You

Want us to get in touch? Provide us with your email address and we’ll be in touch within 24 hours.